Commercial vs Industrial Refrigeration: four key differences

From the grocery store or the supermarket to food processing plants, refrigeration systems ensure the freshness and safety of perishable goods. Have you ever wondered about the differences between the refrigeration systems that power local eateries and those powering massive cold storage warehouses? In this blog post, we’ll explore the nuances between commercial and industrial refrigeration systems. In particular, the differences in scale, complexity, and operational requirements. By the end of this article, you’ll make more informed decisions regarding refrigeration solutions that align with your needs. Whether you’re in the food service industry, pharmaceutical sector, or any other field reliant on cooling technology.

Commercial Refrigeration’s key characteristics

Commercial refrigeration refers to cooling units designed for use in supermarkets, restaurants, grocery and convenience stores, among others. These systems are designed to meet the demands of commercial environments. In other words, it’s necessary to store the food and beverages at an appropriate temperature. Let’s have a look at its main characteristics:

- Size and capacity are tailored to match the volume of perishable goods handled.

Commercial refrigeration systems come in various sizes to accommodate the specific needs of different businesses.

- Commercial systems offer flexibility in temperature control to meet diverse needs.

This characteristic is essential as different products require specific storage conditions to maintain freshness and quality. For example, it can range from standard refrigeration temperatures for beverages to specialized low-temperature settings for frozen foods.

- Energy efficiency is a critical consideration in commercial refrigeration.

Modern systems include energy-efficient compressors, and smart temperature controls to minimize energy consumption without compromising performance.

In the food service industry, commercial refrigeration systems are undoubtedly the guarantee of product quality, the heart of a supermarket. SCM Frigo designs and manufactures some of the most complete ranges of commercial refrigeration equipment. Find out more about our CO2 solutions and applications.

With growing concerns about environmental sustainability, the industry is witnessing a shift towards refrigeration systems that use natural refrigerants, such as CO2. These solutions offer advantages such as low environmental impact, energy efficiency, and regulatory compliance, making them popular choices for commercial applications. If you want to learn more about CO2 refrigeration, explore the principles of this system, as well as its main features and benefits.

Industrial Refrigeration’s key characteristics

Industrial refrigeration systems are designed for large-scale applications, including logistic centers, food processing plants, among others. These systems are engineered to handle larger quantities of goods and maintain precise temperature control across extensive storage areas. Let’s have a look at its main characteristics:

- Industrial refrigeration systems are characterized by their immense size and capacity.

They have to be capable of storing thousands of tons of perishable goods across expansive facilities.

- They are focused on temperature control precision.

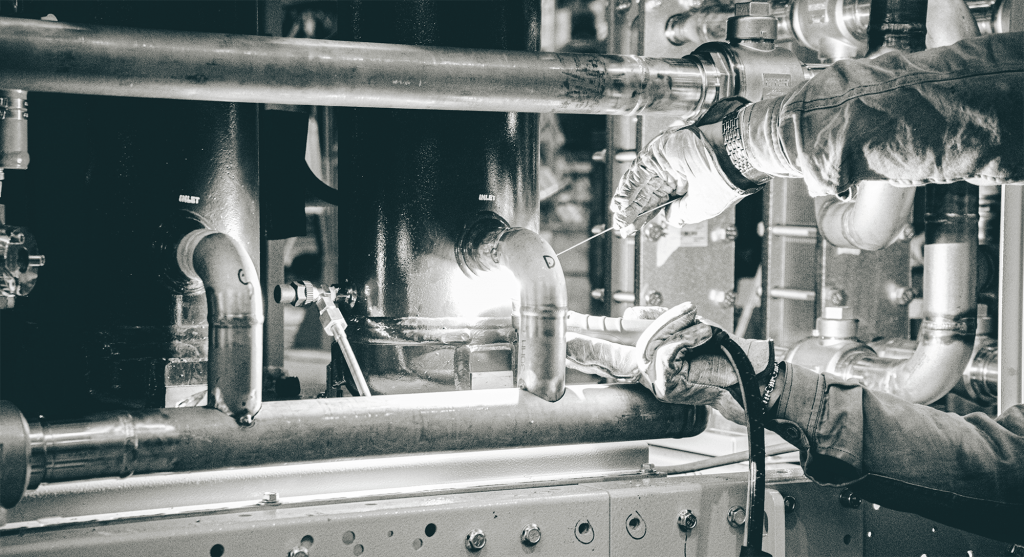

Advanced temperature control mechanisms, including automated monitoring systems and redundant cooling units, ensure consistent and reliable performance.

- Industrial refrigeration systems operate 24 hours a day, facing rigorous demands and challenging environmental conditions.

So, reliability is non-negotiable. Periods of inactivity can result in significant losses. Robust construction, redundant components, and comprehensive maintenance protocols are essential to ensure uninterrupted operation.

In the industry sector, precision, reliability, and scalability are crucial. SCM Frigo designs and manufactures some of the most complete ranges of industrial refrigeration equipment and industrial chillers. Find out more about our CO2 solutions and applications.

For the industrial refrigeration segment, CO2 is also proving its worth by offering several advantages. For example, environmental sustainability, energy efficiency, and versatility. CO2 refrigeration systems provide reliable cooling solutions that meet the requirements of industrial operations while minimizing environmental impact. What sets this system apart, and why is it gaining traction in commercial and industrial refrigeration worldwide? Learn more in this blog post.

Commercial vs Industrial Refrigeration

These types of refrigeration serve distinct purposes, in particular, because they present unique characteristics. In this section, we’ll highlight the key differences between these two types of refrigeration, namely scale, complexity, and operational requirements.

1. Size and scale differences

This distinction emphasizes the different capacities and space requirements between the two types of systems. For example, commercial refrigeration systems are typically smaller. This happens because they serve localized establishments. In contrast, industrial refrigeration systems are designed for large-scale operations, spanning vast warehouses, processing plants, and distribution centres.

2. Precision and complexity of temperature control

They both prioritize temperature control, however the level of precision and complexity differs significantly. Commercial systems often focus on maintaining consistent temperatures within a specified range suitable for storing perishable goods. While industrial refrigeration requires specialized cooling techniques and sophisticated monitoring systems. In the end, the temperature requirements are more stringent.

3. Energy efficiency considerations

Commercial refrigeration prioritizes energy efficiency to minimize operational costs and environmental impact. In industrial systems, energy efficiency is essential but may take a backseat to other factors such as temperature control precision and system reliability. Remember, the industrial applications are on a larger scale and involve other operational requirements. So, this divergence is based on the fact that the two sectors have different priorities and operational requirements.

4. Maintenance and operational demands

Commercial systems typically require regular maintenance to ensure optimal performance and compliance with food safety regulations. However, industrial systems demand more intensive maintenance schedules and specialized expertise due to their complexity and scale. In addition, the fact that they operate continuously requires maintenance protocols to prevent downtime.

Understanding and recognizing these differences is essential for selecting the most suitable refrigeration solution to meet specific operational needs and regulatory requirements.

In conclusion, each refrigeration system serves unique purposes and presents distinct challenges and opportunities. With information on the main differences on your side, we invite you to delve deeper into the world of CO2 refrigeration systems. First, start by answering this question: why use CO² as a refrigerant?

Building Connections

On LinkedIn

Become a CO² Specialist

Beijer Ref Academy will offer technicians and installers the opportunity to learn how to operate CO2 refrigeration systems in different configurations.