How CO2 Heat Pumps are changing Refrigeration?

Heat Pumps using CO2 transcritical technology are advanced products. They are highly effective in transferring heat and regulating temperatures, making CO2 heat pumps better and eco-friendly.

This blog post will discuss the SMART CO2 HP. We’ll cover the market, technological progress, and what’s next. You’ll learn how this technology changed the heating sector and will continue leading the way.

Introduction and Market Overview

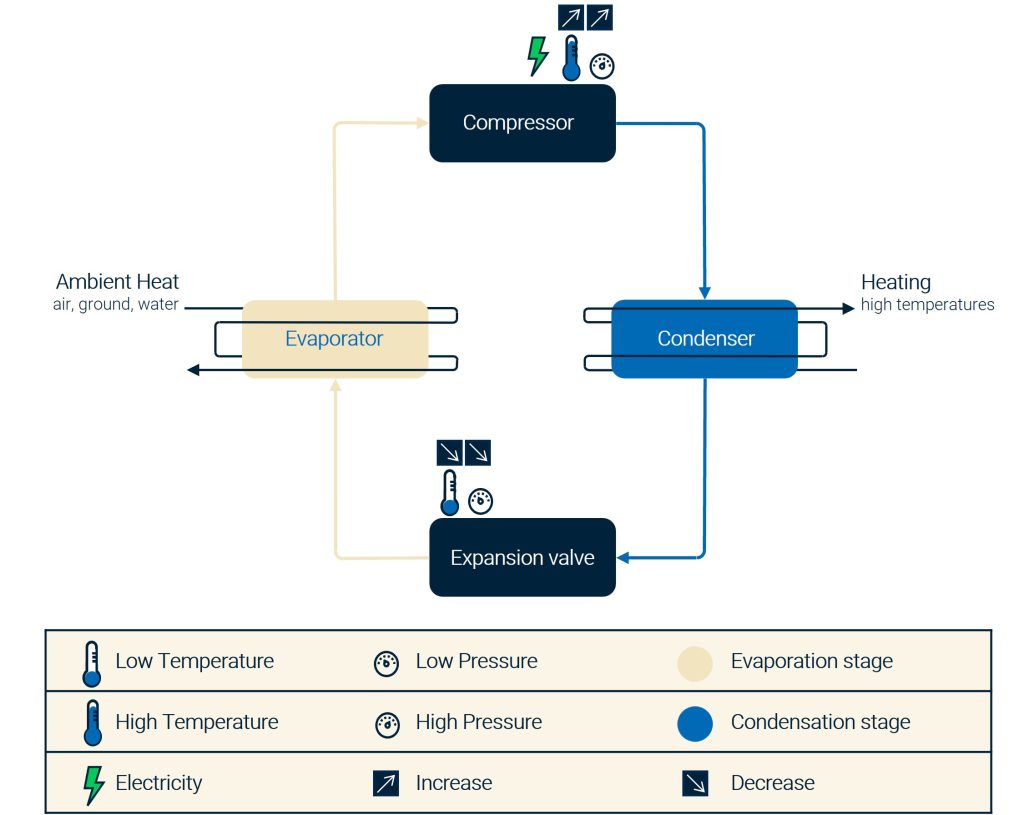

Heat Pumps are a renewable type of heating and cooling system. They operate by utilizing the heat sources available in the surrounding environment to provide a heating or cooling effect to a space.

These heat sources can come from the energy present in the air, water, or ground, and are transferred using CO2 as a refrigerant that is powered by electricity.

Therefore, Heat Pumps are technologies that regulate temperatures based on human needs or industrial and production applications. They rely on the vapor compression cycle to function. In the context of CO2 refrigeration, this technology is essential in maintaining optimal temperature levels and achieving energy-efficient operation.

In Europe, almost 17 million Heat Pumps were installed at the end of 2022, according to the Commission. Manfred Mahnert, SCM Frigo’s International Business Development Director, explains, “Heat Pumps are not the main heating system at the moment. There are a lot of fossil fuel burners like gas and oil, and they are still installed in almost every country in Europe. In 2022, we had about 4 million installations on fossil fuel burning systems”.

Nevertheless, the market is starting to change. “Germany is already transferring from fossil fuel to renewables, the UK is starting with that also. All of Europe will start banning the use of fossil fuel burners to reduce CO2 emissions”. In this way, Manfred defends the following scenario: “70 – 80% of new installations every year will be equipped with Heat Pumps, and 60% of the existing installations will be rebuilt with this technology in the next ten years”.

In numbers, this means that we expect “more than 1 million installations with capacities from 50 – 300kW for heating systems every year and more than 18 million installations with capacities from 50 – 300kW needs to be rebuilt in the next years.

Why Heat Pumps?

CO2 Heat Pumps offer numerous advantages for a sustainable future. They have become increasingly crucial in today’s context. This is due to several important factors:

1. Safe of the planet

By decarbonizing heating systems, CO2 Heat Pumps reduce the environmental impact caused by traditional heating methods.

2. Compliance with New Regulations

The introduction of new F-gas regulations and directives across Europe aim to phase out HFC refrigerants, promoting the adoption of greener technologies.

3. Countries as an example

In the UK, there is a plan to install 600 thousand Heat Pumps annually from 2028 to reduce greenhouse gas emissions from heating. Germany requires new heating systems to utilize at least 65% renewable energy, with a goal of 500 thousand heat pump installations annually from 2025.

4. Energy Security

The shortage and price increase of gas and oil accelerates the shift to Heat Pumps. This fact highlights the importance of renewable energy sources.

5. Market Potential

The transition towards Heat Pump technology opens up significant market opportunities. Due to its importance to combat climate change and enhance energy sustainability.

Technological advancements

CO2 Heat Pumps have come a long way in terms of design and engineering. These solutions offer better performance and efficiency. One area where innovation has been key is in the improvement of compressor technology. Advanced compressor designs, like variable speed and capacity regulation, permanent magnet technology, or scroll compressors, together with ejector technology, allow for precise temperature regulation and superior energy efficiency. This makes them flexible and easy to use, while also reducing energy consumption.

Improvements in the design of heat exchangers have led to increased efficiency in transferring heat. This resulted in better performance of CO2 Heat Pumps. These advancements have also made these systems more compact and versatile. As a result, they can be installed in more flexible ways and can save space.

This year, SCM Frigo presents its SMART Heat Pump, developed in partnership with Fenagy. This technology leverages the power of carbon dioxide, a natural refrigerant, to provide highly efficient and eco-friendly heating and cooling for various applications.

Our main goal was to ensure optimal performance, reliability, and adaptability for diverse settings. In that way, our CO2 heat pump is designed to meet the demands of commercial and industrial processes, offering energy-efficient solutions for both applications.

“Future wise, this heat pump will be available as a water-to-water heat pump and air-to-water. The range goes from a light commercial to light industrial, so between 30-40 kW up to 300-350 kW on heating capacity. This heat pump will be a heat pump with natural refrigerant, so it will be a sustainable solution”, Manfred explains.

Now is the time for businesses to keep up with the latest Heat Pump products with CO2 transcritical technology. They can benefit from increased efficiency in commercial building applications, hot water production, industrial processes such as food processing, and HVAC systems.

Are you looking to improve your heating processes while minimizing costs? Our team of industry experts and suppliers can help you access the latest Heat Pump solutions tailored to your specific needs and applications. Interested in finding out how a CO2 Refrigeration System can benefit your company? Contact us to learn more.

Building Connections

On LinkedIn

Become a CO² Specialist

Beijer Ref Academy will offer technicians and installers the opportunity to learn how to operate CO2 refrigeration systems in different configurations.