MAINTENANCE FAQ

How does the liquid line filter replacement procedure take place?

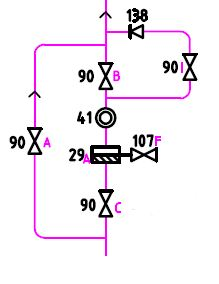

Change liquid filter dryer:

- Ensure valve 90I is open before carrying out any works.

- Attach a suitably rated gauge manifold to ¼” connection 107F.

- Close drier entry valve 90c and allow the pack to pump down for 10 minutes.

- Again ensure valve 90I is open and then shut dryer outlet valve 90B and open dryer bypass valve 90A slowly.

- Close valve 90I and immediately vent the remaining refrigerant through gauge manifold to a well ventilated area.

- Once pressure has equalised and any frost line on the dryer end plate has melted remove drier housing end plate and replace gasket.

- Install new filter drier core and replace housing end plate immediately. Evacuate drier housing to 0.5 mbar.

- Break vacuum with CO2 vapour to >6 bar.

- Close valve 107F and remove gauge manifold.

- Open shut off valves 90I, 90C & 90B.

- Close valves 90A