MAINTENANCE FAQ

How does the oil separator filter replacement procedure take place?

Removal and replacement of coalescent oil separator filter:

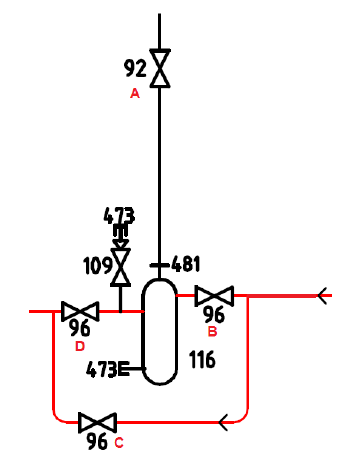

NOTE: If the unit is equipped with bypass on the oil separator, there is no need to stop the compressor to change the filter core.

Procedure:

- Set inverter compressor max frequency to 50 Hz.

- Open valve 96C.

- Close valves 96A, 96B & 92A.

- Pump down pack as per Pump Down Procedure.

- Remove the cup from the top of valve 109.

- Connect on ¼ flare connection a suitable pipe and vent pressure from inside the oil separator by opening the valve (ensure pressure is vented to a well ventilated area).

Vent pressure from oil separator into a suitable oil container to stop oil contamination to the environment. - Once pressure has equalised with atmosphere verify by attaching a suitably rated gauge manifold and setting discharge service valve open ½ way.

- Remove separator top plate and replace filter and O-ring/gasket as per manufacturer’s instructions.

- Replace separator top plate as per manufacturer’s instruction ensuring the correct torque is applied to all fixings.

- Evacuate the separator and compressor 1 to 0.5 torr by attaching a vacuum pump to the HP service port on compressor 1.

- Once 0.5 torr is achieved, isolate the vacuum pump and break vacuum with vapour CO2 up to 10 bar.

- After this is completed ensure pressure reading > 5barg.

- If reading lower repeat vacuum break procedure.

- Open oil shut off valve 92A.

- Open valves 96B & 96D.

- Close valve 96C